Introduction

Barrettes are piles similar to large diameter bored piles but they are in rectangular section instead of circular. They can be orientated to accommodate high horizontal forces and bending moments in addition to vertical loads. Barrettes are mainly used in the foundations of heavy structures.

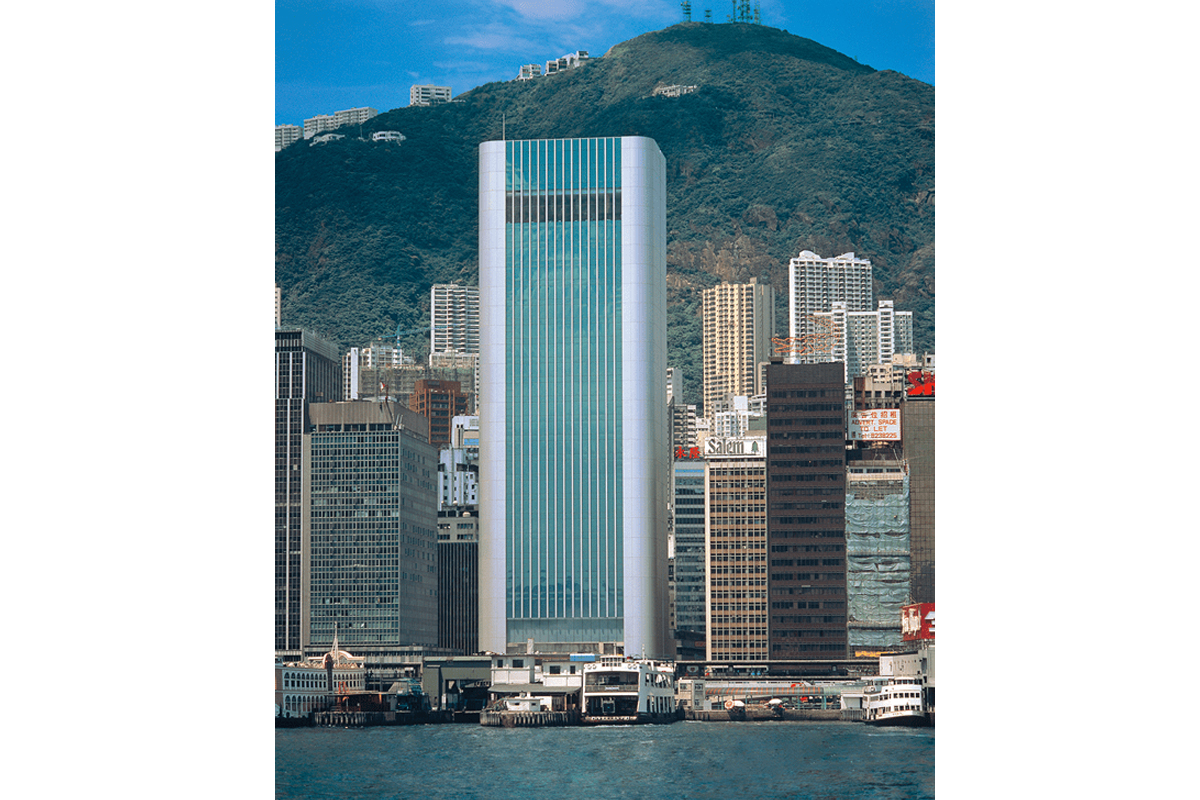

Usually barrettes are made of reinforced cast-in-situ concrete. Their thickness ranges from 800mm to 1500mm. They can be installed to a depth exceeding 100m, and their load bearing capacity can be increased by applying shaft grouting technique to increase their skin frictions. The concept of shaft grouted barrettes was, for the first time in Hong Kong, introduced by Bachy Soletanche for the foundation of KCRC Nam Cheong Station in 1999 and has, since then, been used on several other projects such as ICC tower (485m tall) in Hong Kong.

General Processes

Barrettes are constructed using the same technique as diaphragm wall. They are excavated by grab, chisel, and/or hydrofraise under carrier fluids such as bentonite or polymer. The purpose of bentonite or polymer is to stabilize the open trench. The general principle is to maintain a positive hydrostatic fluid load in the trench above groundwater level.

The general construction sequences of barrettes are as follows:

- Construct temporary reinforced guide walls,

- to provide physical confirmation of barrette location,

- to guide the excavation tool,

- to maintain the carrier fluids to required level,

- to support the steel reinforcement.

- Excavate the barrette to required depth by grab, chisel and/or hydrofraise,

- Desanding / substitution of the carrier fluids and barrette base cleaning,

- Installation of steel reinforcement,

- Concreting of barrette by tremie method.